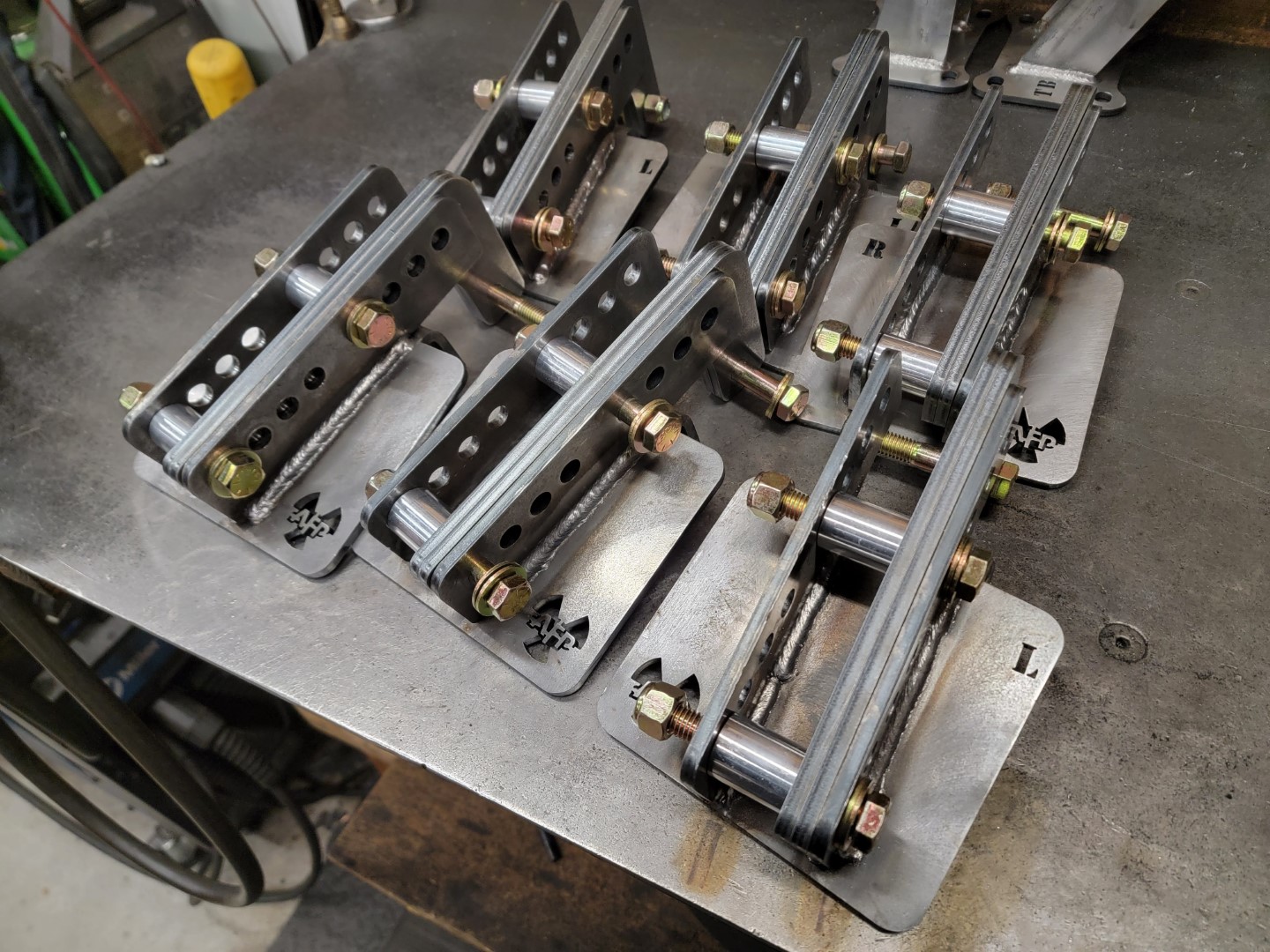

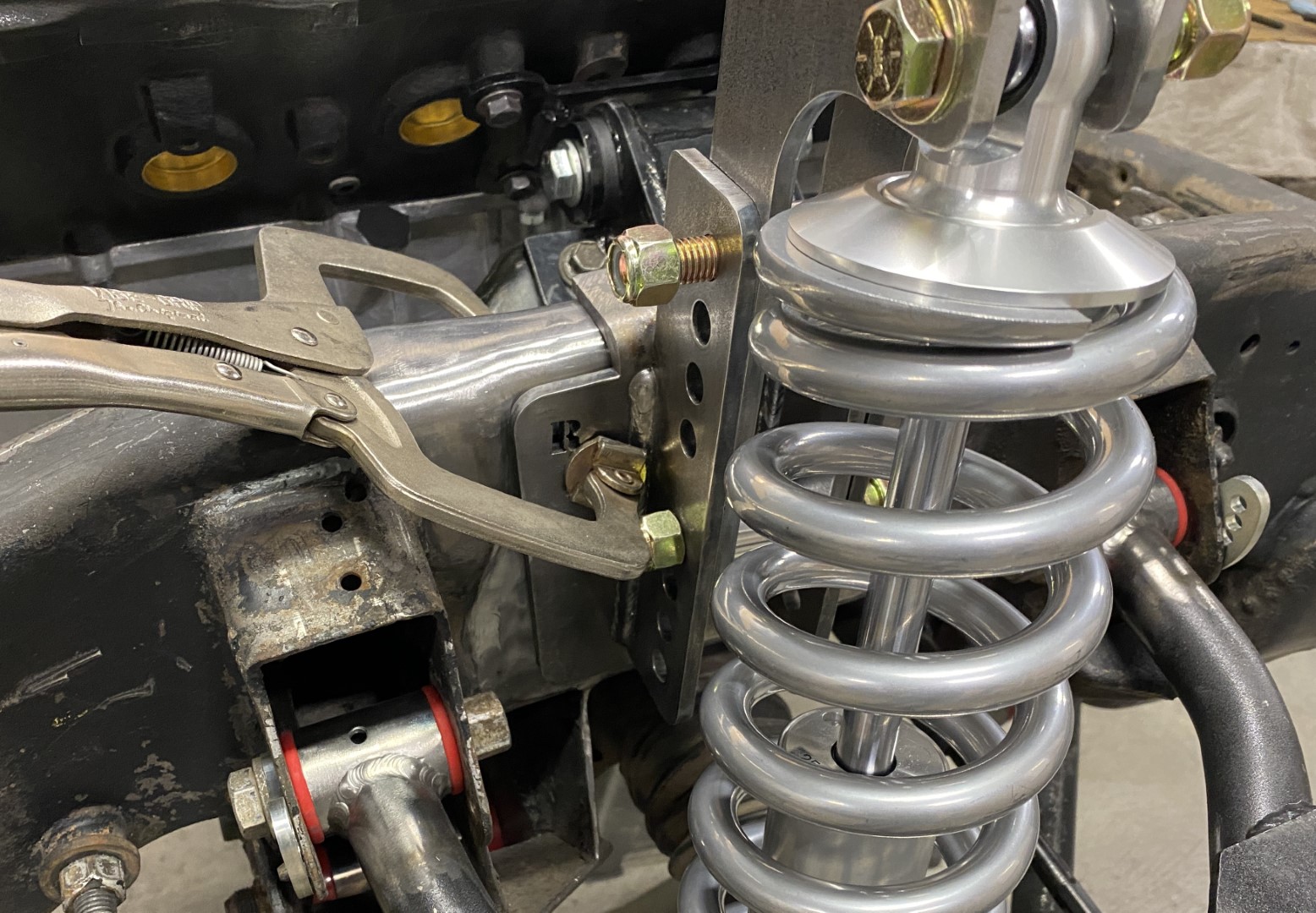

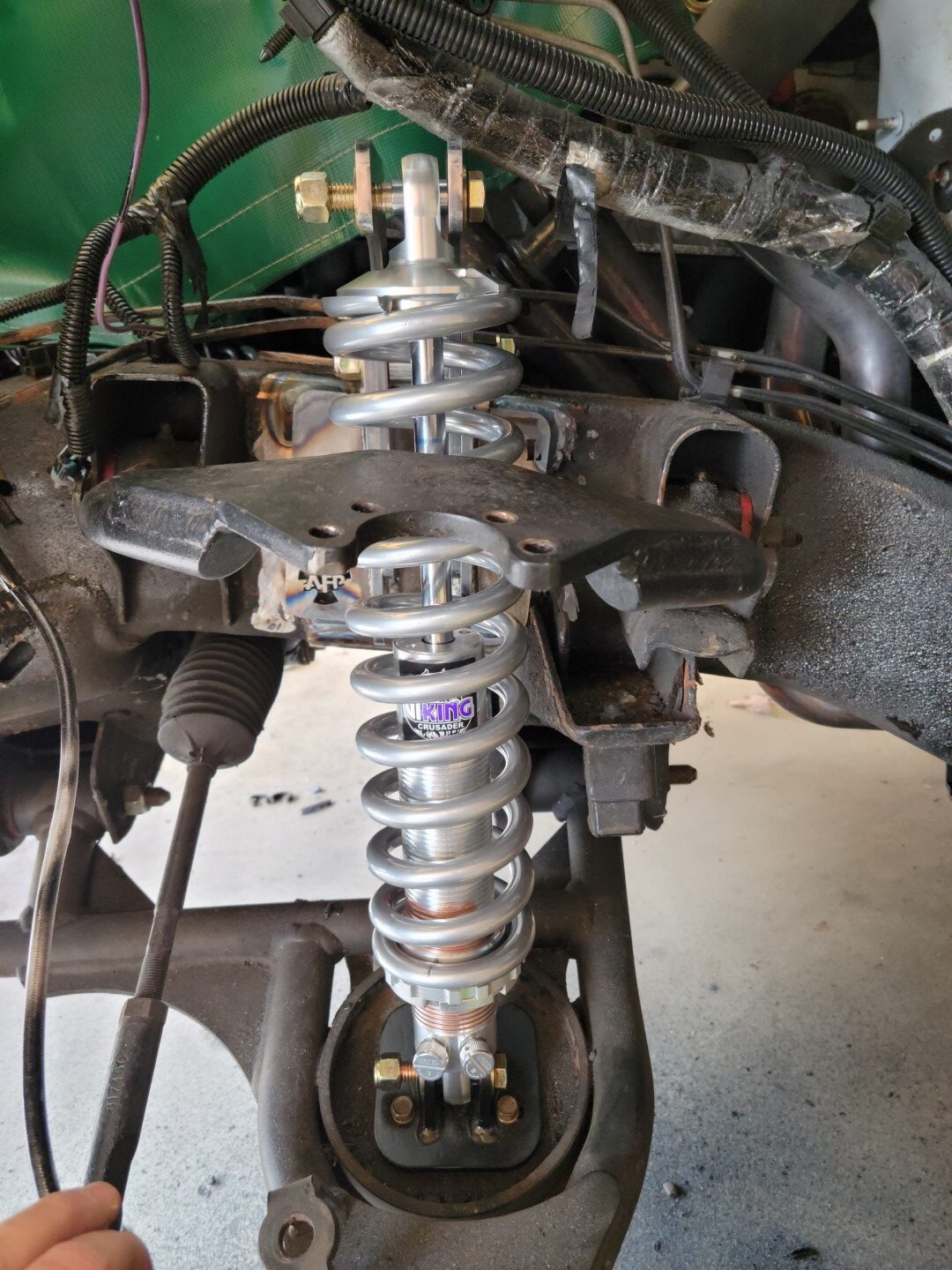

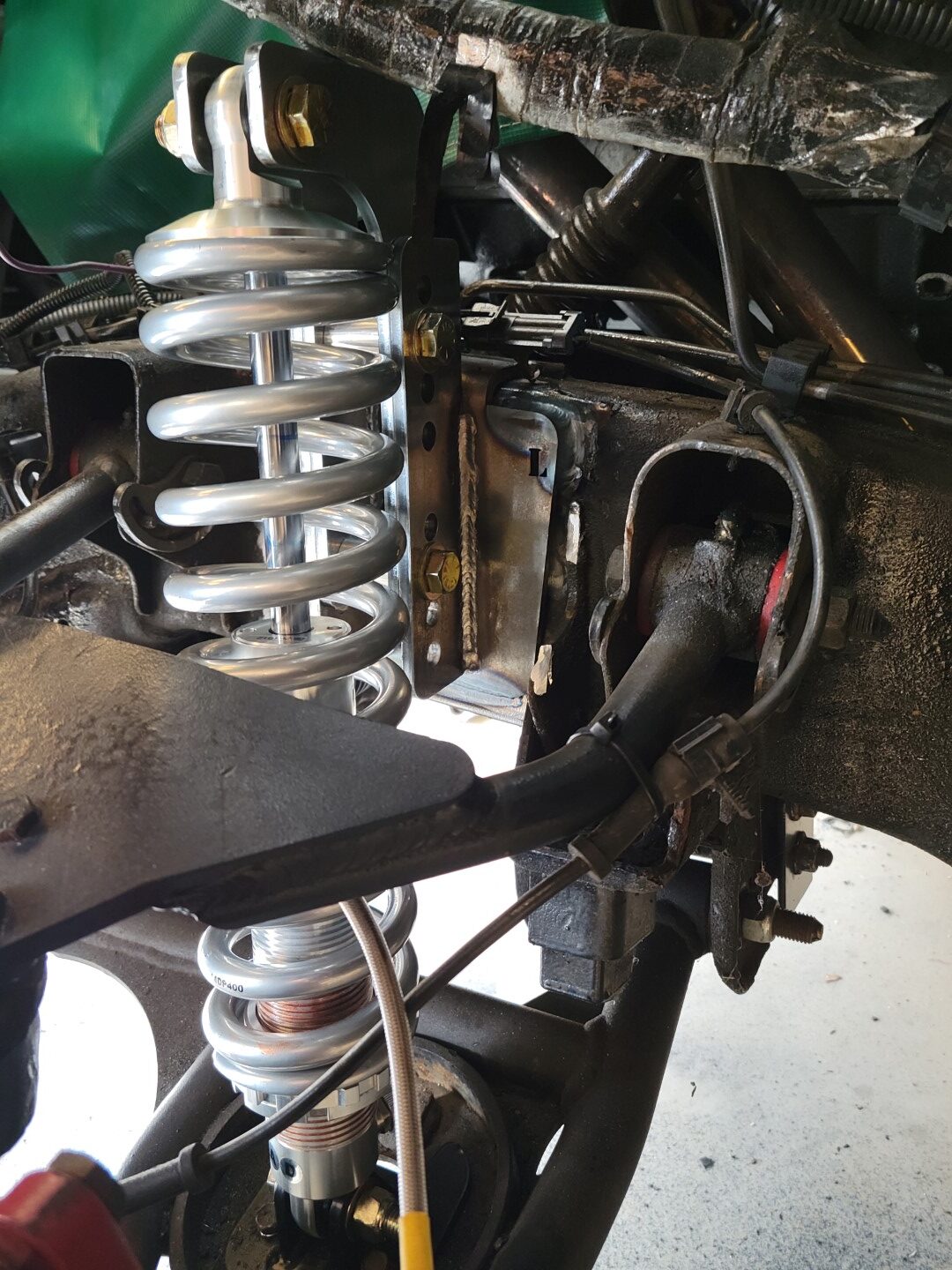

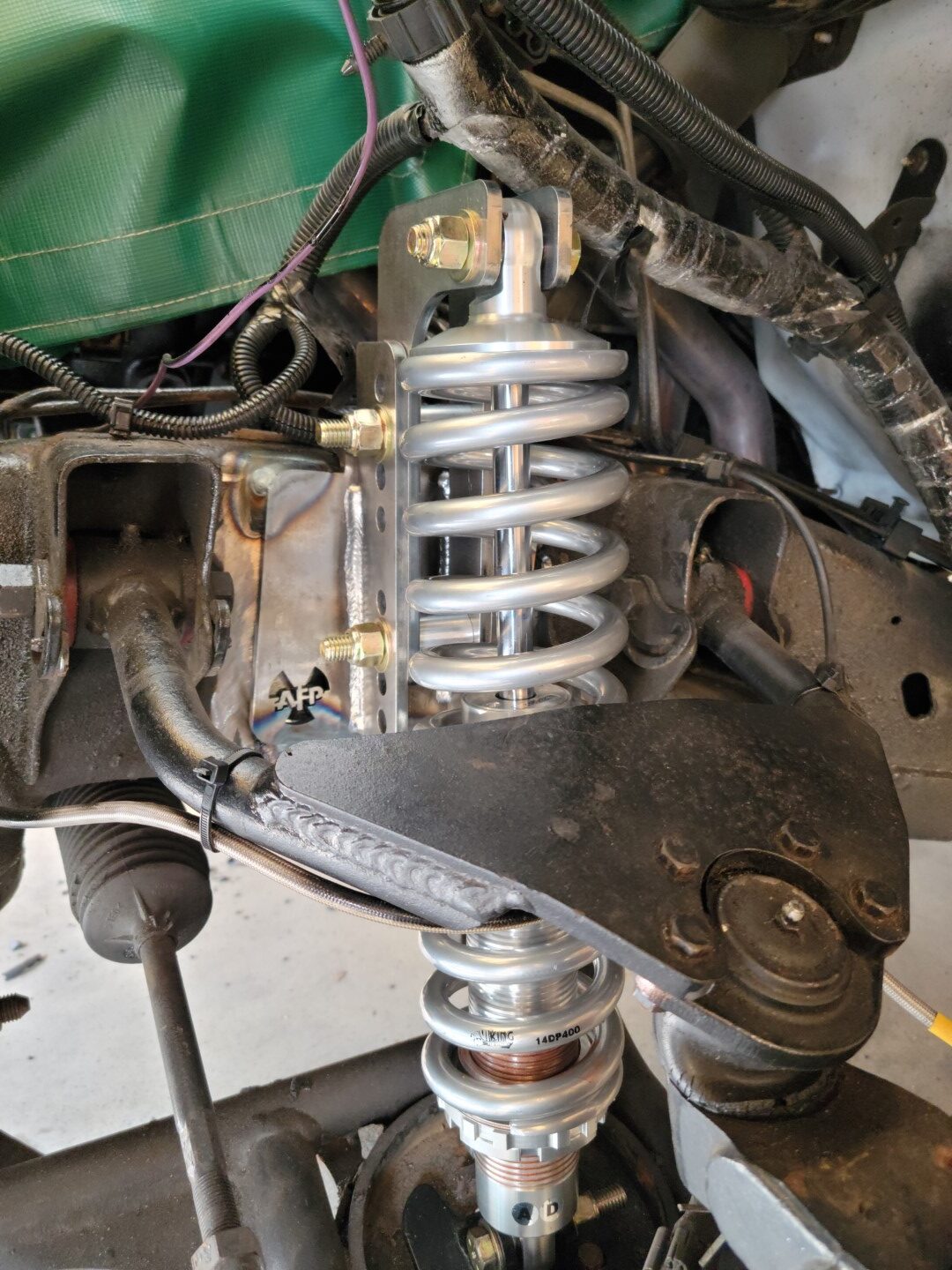

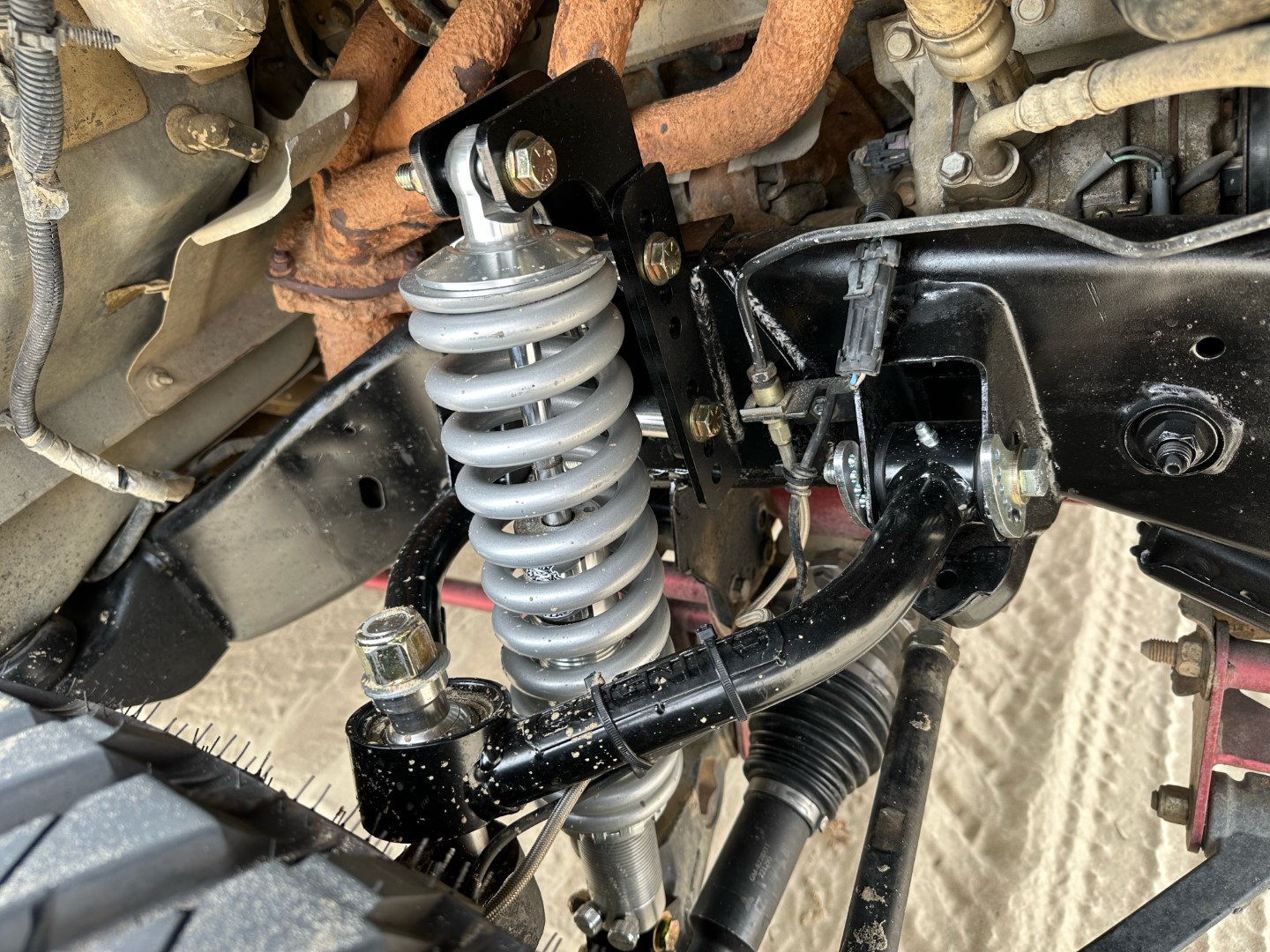

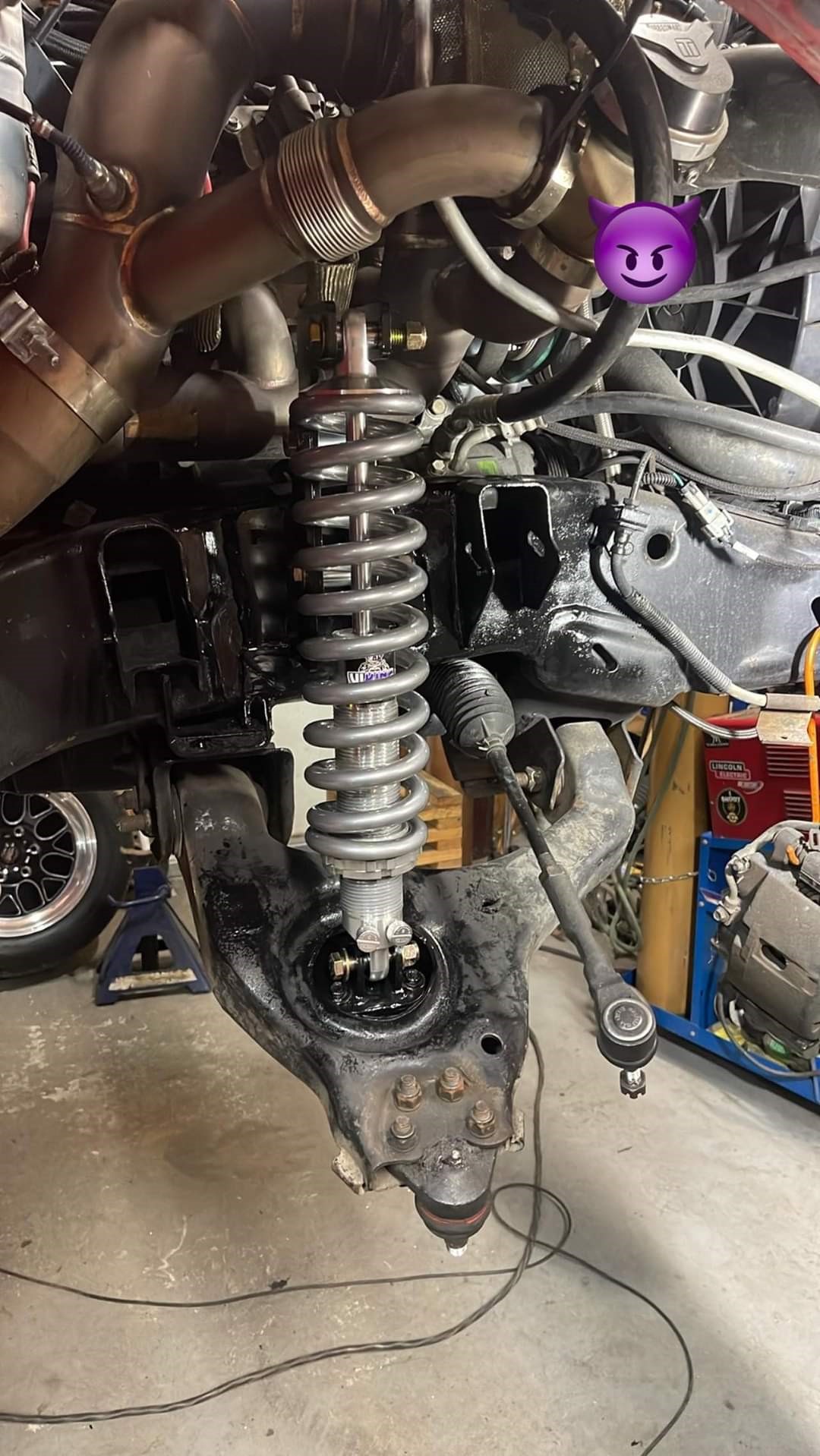

These are weld-on upper coilover mounts to replace the stock shock perch on both 2wd and 4wd 99-06 GMT800 1500 trucks. You could call these “long-travel” brackets but I personally don’t like that term as it can be misleading. These require the removal of the factory mounts and need to be welded to the frame. They are laser cut 1/4″ thick steel on the base plate and shock tabs and 3/8″ thick steel for the mounting struts. This utilizes 2 parallel mounting braces instead of a single center one for maximum strength and stability. The mounting angle is offset to insure the shock is aligned with the lower mount to prevent any shock binding during travel. Completely designed in SolidWorks. You will need a suitable welder and fabrication skills (or access to someone who does) to install these (should be welded all the way around the perimeter and top). These are meant for the more serious guy who needs more flexibility with their setup than the normal bolt-on style kits (available elsewhere on my site).

The main advantage to these mounts are they give you much more room for mounting an aftermarket coilover especially when lowering the truck. They have 4 holes are spaced 7/8″ apart to allow you to adjust your ride height without changing shock preload, or adapt to whatever shock you have available. You are able to substantially lower your truck using the factory control arms without any need for aftermarket replacements (may need offset UCA bushings or aftermarket UCA simply for alignment purposes if going very low). If you are wanting a lot of front end travel with a low ride height (popular in “no-prep” racing) then this is what you need.

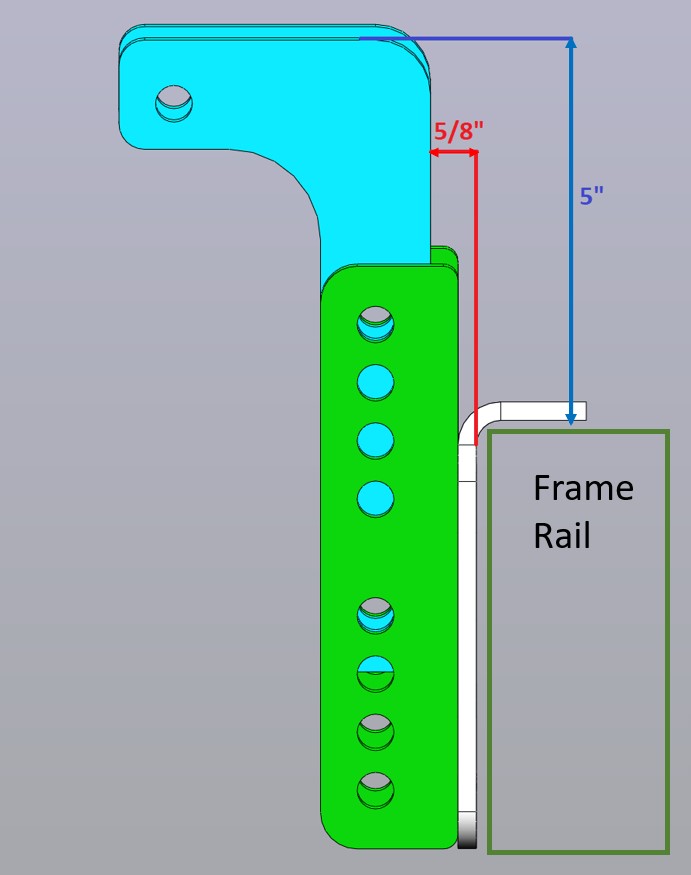

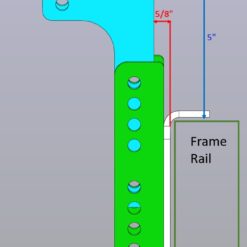

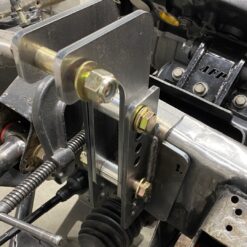

At the highest position the shock mounting hole center is 4.5″ above the frame rail (2.15″ at the lowest setting) and 4.25″ outboard from the frame. Grade 8 hardware and nylon locking nuts are used throughout. All bolts are grade 8 1/2″ diameter. The inner spacers are machined aluminum to take up any slack when bolted together and prevent any warping of the flanges to keep them parallel. The back of the bracket is press bent 90 degrees to make vertical location easy (tab sits on top of the frame). Front to back (left to right) location may vary slightly but should be done in such a way as to most vertically align the shock with the lower control arm mount. Distance between shock tabs is 1.25″ when installed inboard of the frame tabs so will fit multiple shock brands (bearings are typically 1″ to 1.5″ on most aftermarket shocks). Brackets are shipped raw and should be painted or sealed after installation to prevent rust. Weight is approximately 8lb per side.

Installation Tips

-The driver side is relatively easy since the frame is flat.

-The passenger side will need to be clamped in both the top left and bottom right corners to properly form the frame since it is not perfectly flat. Later designs have the top left corner cut at an angle to better accommodate the frame shape so will be slightly different than the website picture.

-Be sure to allow space for the bolts to be inserted and removed, they may be close to the UCA mount on the frame in certain directions.

-4WD trucks on the passenger side may need to grind/cut the lip of the box section on the bottom for the mount to sit flat on the frame.

| Weight | 16 lbs |

|---|---|

| Include Lower Control Arm Bracket | No, I only want the upper brackets, Yes, I have a 2wd with stock LCA (+$145), Yes, I have a 2wd with DJM/IHC LCA (+$145), Yes, I have a 4wd torsion bar truck with stock LCA (+$200) |

| 2WD or 4WD/AWD | 2WD truck, 4WD/AWD truck |

Reviews

There are no reviews yet.