LS Truck HD Belt Tensioner Kit

$65.00 – $300.00

This is a tensioner kit to be used on factory style truck waterpumps to allow easy mounting of an off the shelf HD tensioner. See below for more info.

This is a bracket/kit to be used on factory style truck waterpumps to allow easy mounting of an off the shelf HD tensioner. This is especially useful for LSA swapped trucks that use the LSA supercharger on the factory 6 rib system. This is also recommended for high-rpm vehicles to keep the belt on if you experience that issue. I now offer the bracket and a HD 6-rib flanged pulley tensioner as a kit. This purchase includes the bracket and the center grade 12.9 bolt, locking nylon nut, and 2 washers. This is made from 3/8″ steel, it is very strong and utilizes all 3 mounting points to the water pump. The 3 factory mounting bolts are reused or new stainless allen head ones are included if that option above is selected. A spring-loaded automatic tensioner is preferred over a manual style tensioner whenever possible since it will accommodate natural belt stretch and is also easier on bearings when loaded. If the bracket is ordered raw it must be painted, powdercoated, or sealed or it will rust relatively quickly.

6 Rib vs 8 Rib Pulley Options

You can use a 6 rib belt on an 8 rib tensioner, it will just run in the middle (empty rib on each side) with factory truck accessory spacing but could possibly walk forward or backward. If you have a supercharger with an 8 rib conversion you will obviously need the 8rib pulley. I now make a custom 6 rib pulley for this kit that is ideal for 6 rib systems. The 6 rib tensioner is aligned exactly to stock belt path and functions similar to the stock tensioner, just with more tension force and stretch range. If you order one of the 6 rib options the pulley will be pre-installed for you. If you should ever have to keep the pulley off keep in mind they are LEFT HAND threads and will strip easily if overtorqued since the tensioner body is aluminum.

Mounting and Installation

There are several mounting positions which can be used for the tensioner tab to rotate the tensioner to whatever position works best for you. Depending on belt length and accessories the tensioner will generally point straight up when completely unloaded when installed, but can be rotated as needed. On a newer bracket design there may be just 5 holes instead of the normal 16. This is because the other ones are not able to be used anyway eliminating some confusion. Generally the middle of the 5 holes is the best place to start, but rotate as needed to get the most travel as possible. Ideally you want to have to tighten the tensioner to its full stop and just barely be able to get the belt on all of the pullies. In this way the tensioner has the most room to work and accommodate belt stretch. If the tensioner ever takes up all of its travel the belt will be loose and probably walk or be thrown off. If the tensioner is rotated too far counter clockwise (or too long of a belt is used) the belt may rub the tensioner body from the crank pulley. If the tensioner is rotated too far clockwise (or too short of a belt) the belt may rub the water pump pulley.

Belts

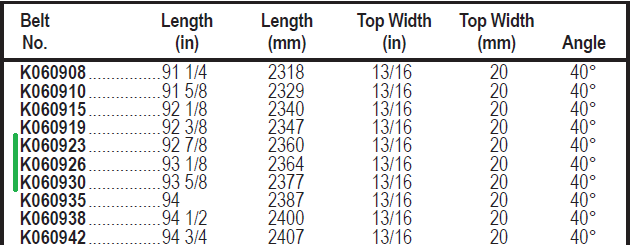

A stock or close to stock belt length should work depending on your pulley combination. The larger case 145a alternator, OD crank pulley, OD alternator pulley, or any other larger pulley will require a longer than stock belt. Any underdrive pullies will shorten the belt needed. If any accessories are eliminated or non-stock belt routing is used that will shorten the required belt. A stock Silverado belt is roughly 93″. Below is a list of Gates belts that will be compatible with the 6rib tensioner based on complete setup.

The part numbers should be easy to cross-refence to another brand if you prefer.

| Weight | 3 lbs |

|---|---|

| Bracket Finish | Raw (-$5), Black, No Bracket (Tensioner Only) |

| HD Tensioner Included | None (Bracket Only), Heavy Duty Gates Tensioner (+$130) |

| Pulley for Included Tensioner | None (Bracket Only), Aluminum 6 Rib (+$95), Steel 6 Rib (+$65), Steel 8 Rib (+$0) |

| Hardware | None, New Stainless Mounting Bolts (+$5) |

Reviews

There are no reviews yet.